Automotive Power Connector Test

- Categories: Vehicle Electronics

- Time of issue: 2022-12-05 10:03

(Summary description)

Automotive Power Connector Test

(Summary description)

- Categories:Vehicle Electronics

- Time of issue:2022-12-05 10:03

- Views:

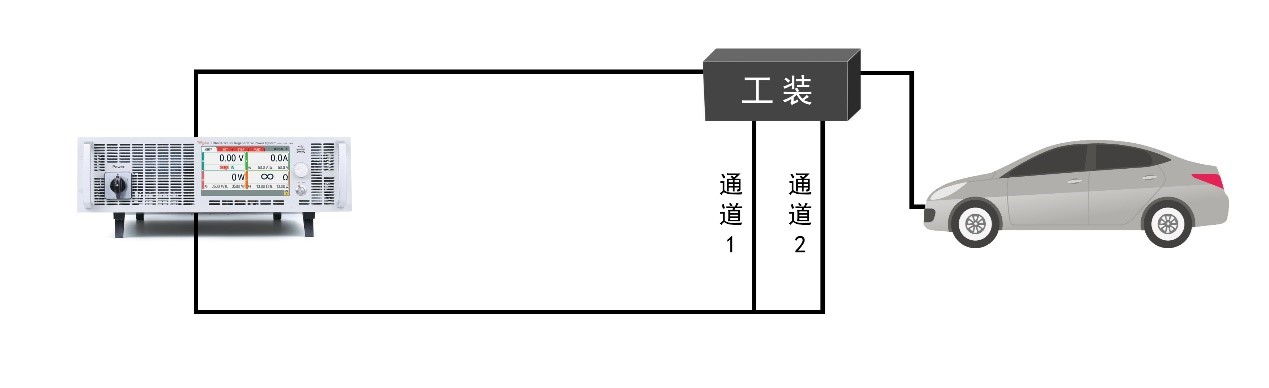

The "power connector" in automotive electronics is a device used to connect power to a circuit and is used to connect a high-current connector to a circuit. Important factors to consider for power connectors are the maximum voltage and maximum current characteristics. The isolation between connector pins is also an important indicator, and the requirements for leakage current are very high. In addition, the butt connection of the power connector is quite tight. It is very important to connect and disconnect, separate the plug and socket to prevent damage, and a power load test is required.

Solution Details,

Testing requirements:

1. Functional test: normal working continuity test

2. Over-current test: Set several points for current cycle test according to the requirements, and at the same time check that the voltage drop at both ends of the line meets the set range, and at the same time observe that the product has no breakdown or arc flash.

3. Impact test: After the product and the harness connector have been plugged and unplugged for more than 10 times, they are paired, and the required current is tested in the form of a half-sine impact pulse to test whether the product surface is deformed or cracked.

4. High and low temperature aging: put the product in the temperature box and load the current according to the requirements, and the temperature box is controlled to cycle between the required temperatures for 24 hours. Test whether there is deformation or crack on the surface of the product.

Instruments List,

TH6680 Series

Scan the QR code to read on your phone

Related Solutions

Feedback